How To Unarchive A Story On Instagram? A Step-by-Step Guide

Jan 28, 2026

Jan 28, 2026

Jan 27, 2026

Jan 24, 2026

Jan 23, 2026

Jan 22, 2026

Jan 22, 2026

Jan 21, 2026

Jan 21, 2026

Sorry, but nothing matched your search "". Please try again with some different keywords.

Effective mixing systems are essential for manufacturing high-quality, consistent products in food, beverage, pharmaceutical, and chemical production.

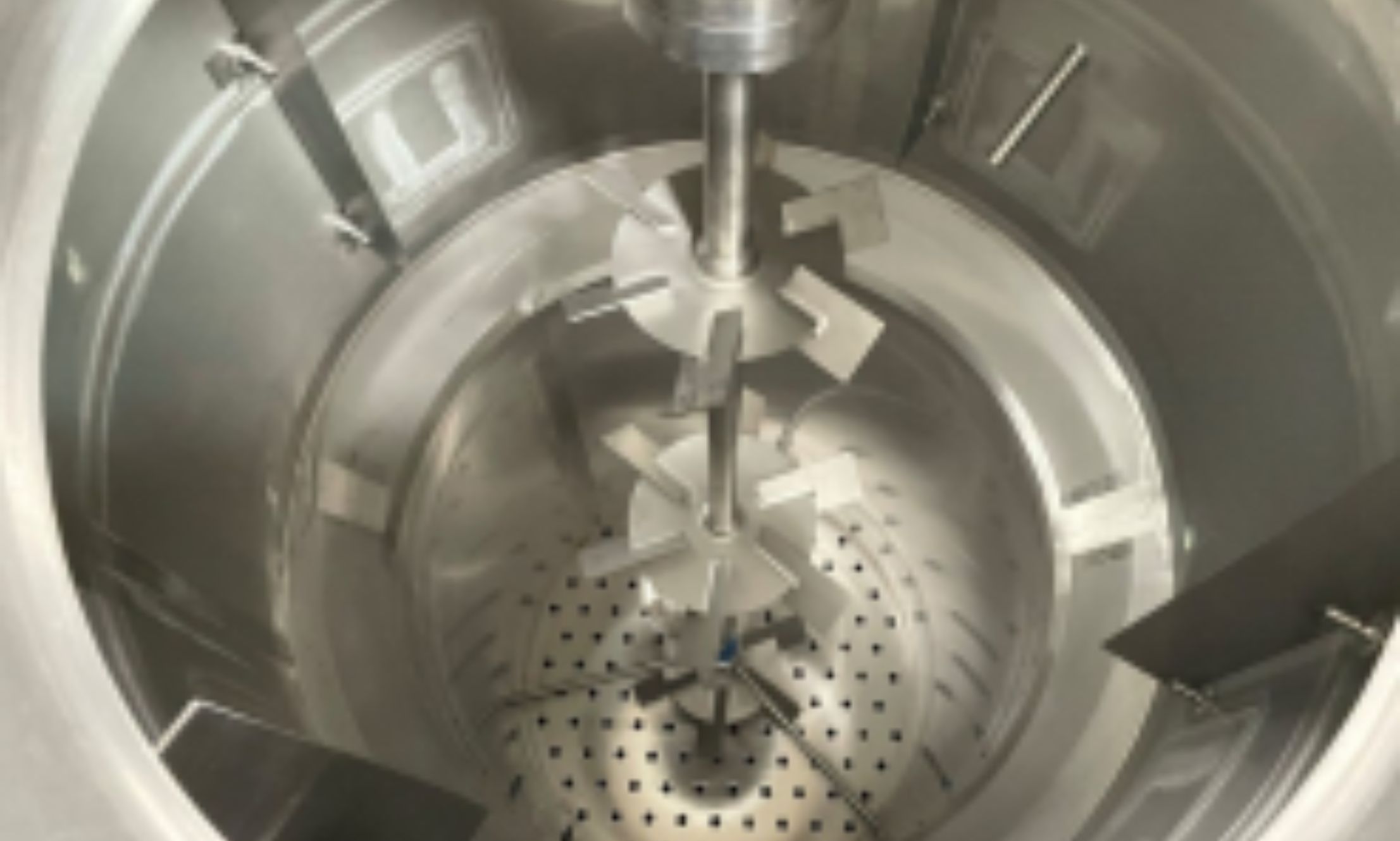

Within these systems lie stainless steel agitators instrumental in maintaining consistency, avoiding contamination, and streamlining production processes.

This article will discuss how these precision-machined components enhance batch consistency and higher product quality.

Proper agitation is a critical component of process engineering. If ingredients are not well mixed, products can experience variable texture, flavor fluctuations, inhomogeneous distribution of active ingredients, and loss of efficacy.

The ramifications can include subtle quality defects to full batch failures, each with high monetary impact.

You should treat the agitator as the backbone of your mixing equipment. It generates the mechanical energy required for proper ingredient dispersion, suspension, and homogenization.

Material choice, design criteria, and operating conditions of your agitation system greatly affect the uniformity of your end product.

Stainless steel has become the gold standard material for industrial agitators for several good reasons.

The austenitic stainless steels 300 series, specifically grades 304 and 316L, provide outstanding corrosion resistance, low risk of product contamination, and excellent durability in high-performance environments.

Stainless steel’s porosity-free surface resists bacterial housing and facilitates easy cleaning to a great extent.

This feature is especially beneficial in sanitary uses, like food, drink, and pharmaceutical production, where avoiding cross-contamination is critical.

The material’s mechanical strength allows for high-torque operation without deformation, with consistent performance even under severe mixing conditions.

Moreover, stainless steel resists exposure to harsh chemicals, extreme temperatures, and repeated cleaning cycles without degradation.

The design of stainless steel agitators affects their performance. Engineers must carefully plan impeller type, diameter, pitch, and positioning based on specific application requirements.

It is recommended that you work with suppliers who have detailed knowledge of fluid dynamics to guarantee that you receive the correct agitators for your process. Helical ribbon or anchor design could provide the best results for products with high viscosities.

On the other hand, hydrofoil or pitched-blade turbine impellers might be suitable for low-viscosity applications, ensuring efficient flow patterns while reducing power consumption.

The use of baffles inside tanks also increases the efficiency of mixing by breaking the circular flow and inducing vertical movement. This pattern of vertical flow is responsible for complete integration of ingredients within the batch.

Industrial agitators in Pharmaceuticals are used in different stages of life, such as,

Industrial agitators combine active ingredients, such as excipients, and ensure uniform distribution.

They are used to maintain the homogeneity of the suspensions in order to prevent the sedimentation of the solid particles.

While manufacturing tablets, these agitators are used to ensure that the powders are mixed evenly before they are compressed.

The agitators are known to dissolve solids into liquids, creating a solution that is used to create injectable medicines or syrups.

Regarding biopharmaceuticals, these agitators are known to create an optimal condition for the fermentation processes used to produce the vaccines and antibiotics.

You must choose the right gallon or size of your mixing tank. If you are wrong in choosing the right size then it would be inefficient, a total waste of space and you will be spending much more than is needed.

If you have a small brewery pub then a fermentation tank of about 30 gallons is perfectly fine. But if you want you can also get 50-gallon tanks.

But once your brewery starts growing, you will have to get 100 to even 1000-gallon tanks for fermentation purposes.

| Tank Size (Gallon) | Typical Applications | Considerations |

|---|---|---|

| 10 –30 Gallon | Pilot batches, small startups (nano-breweries), R&D, additives | Fits into small spaces, easier for manual tasks |

| 50 – 100 Gallon | Small brewpubs, moderate batch sizes, test kitchens | Good balance; useful batch size, manageable footprint |

| 200 – 500 Gallon | Growing craft breweries, mid-size food processing plants | Needs more floor space, often benefits from CIP |

| 1000 + Gallon | Regional/large breweries, large-scale food/beverage plants | Major space/utility needs, bigger investment |

To fit your standards perfectly, it is important that you get customized stainless steel, so else you are gonna find these tanks perfectly fitting your standards.

So here are a few ways you can customize a mixing tank to your liking:

Whether you want a taller and skinnier mixing tank or a shorter and wider tank to fit your space, it can be well adjusted and customized.

Depending on where you want to place the tank, the inlet, outlet, sensor connections, and sample valves need to be installed. All of these can be easily customized according to your standards.

With every tank, it is not possible to remove each drop because of the shape of the bottom, but the shape of the bottom can be customized depending on your needs.

If you want a cone shaped bottom with a specific type of slope, then it can be customized to your needs. These cone shaped bottoms are very popular among customers.

If you have a specific tank shape in mind, it can be customizable to fit your needs. Even the motor mounts and internal baffles can be customizable to suit your needs.

Periodic maintenance and inspection of stainless steel agitators ensure their performance and operational life are in maintainance.

Alignment verification, bearing condition, and seal integrity checks prevent sudden failures that may affect product quality and reliability.

Implement a preventative maintenance program that involves vibration analysis, torque monitoring, and visual inspections.

These proactive steps detect potential problems before they cause product inconsistencies or expensive downtime.

Stainless steel agitators are a key investment in quality control manufacturing. Their role in batch consistency, product purity, and operational efficiency makes them indispensable to today’s processing plants.

Proper design selection, effective maintenance procedures, and knowledge of mixing principles enable manufacturers to use these precision tools to produce superior products with outstanding consistency.

Nabamita Sinha loves to write about lifestyle and pop-culture. In her free time, she loves to watch movies and TV series and experiment with food. Her favorite niche topics are fashion, lifestyle, travel, and gossip content. Her style of writing is creative and quirky.

View all Posts